1

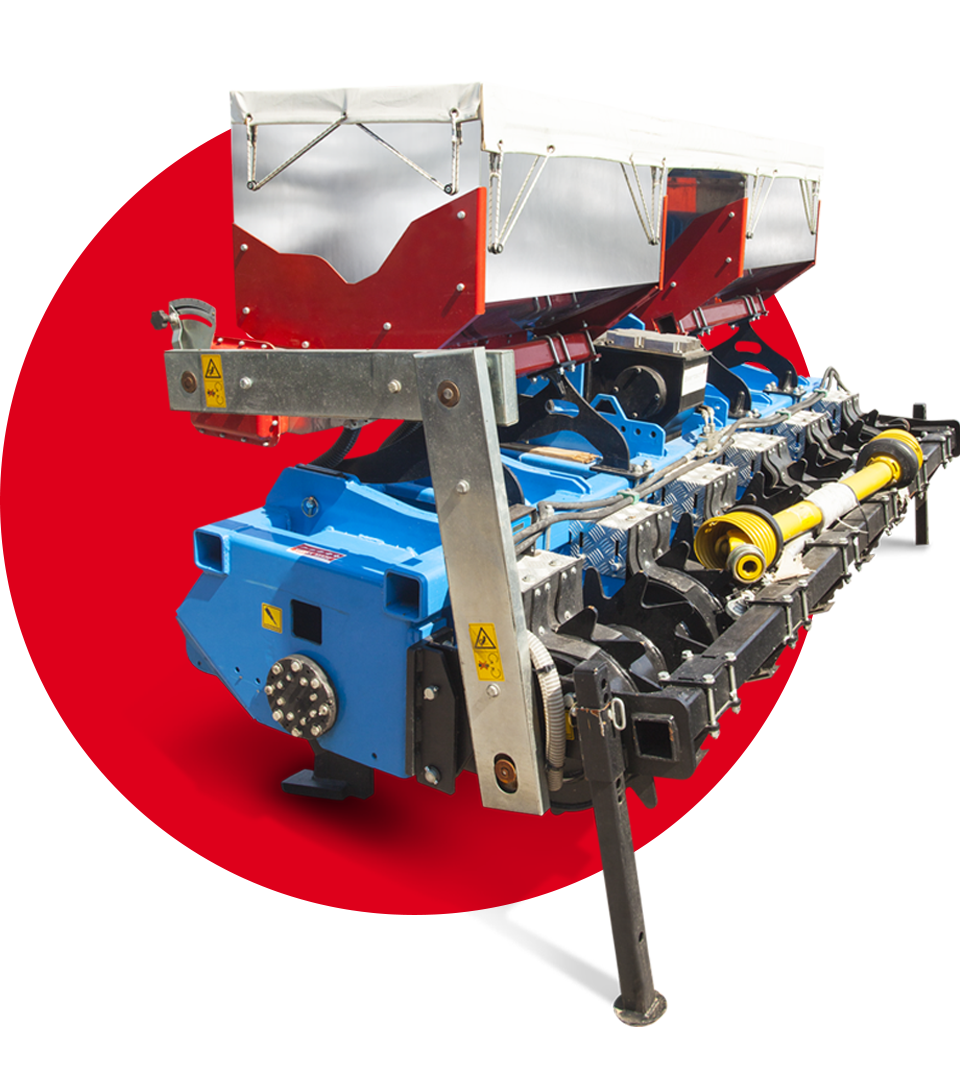

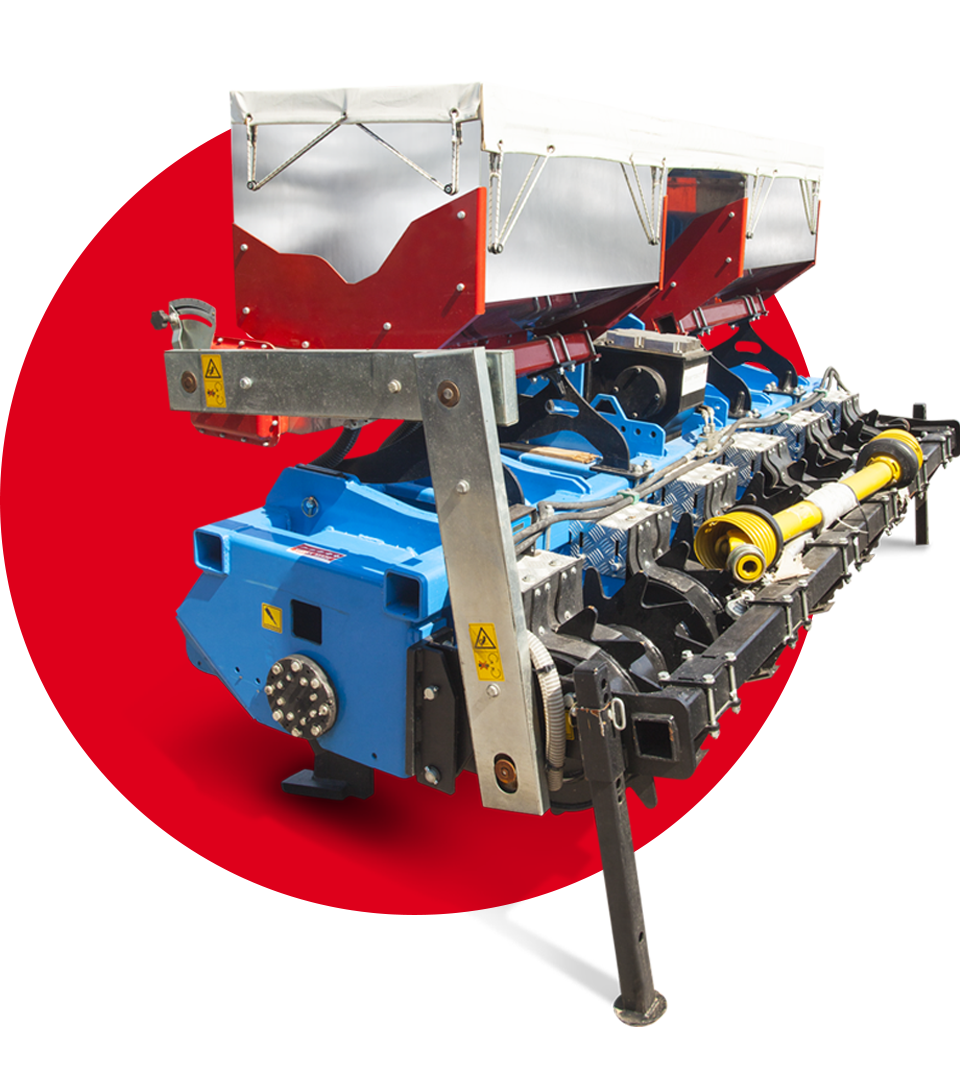

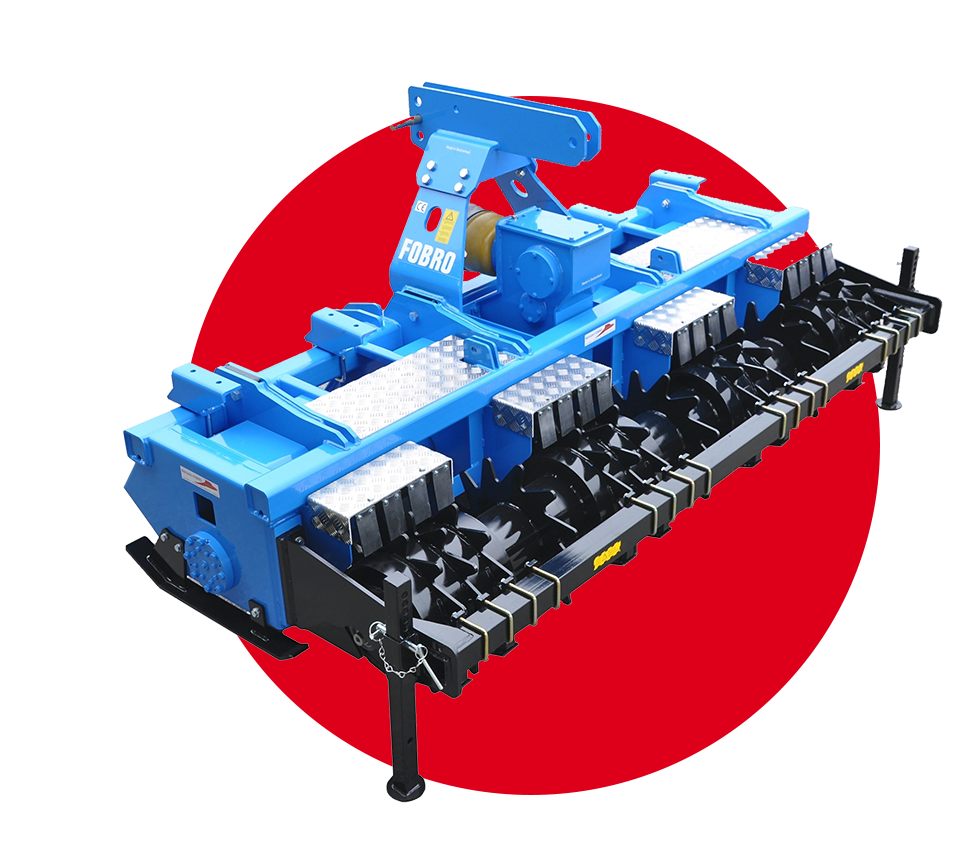

ROTOR STRIP TILL

SIMPLE AND

SUCCESSFUL

SYSTEM

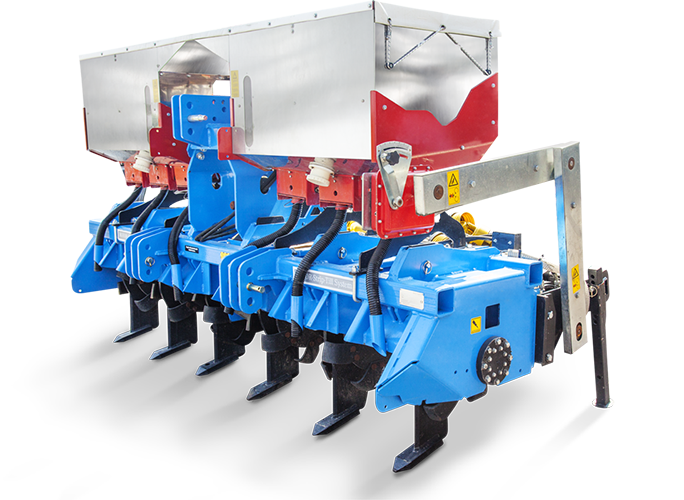

The culti packer roller secures tight soil to seed contact.

And this is how simple the ploughless Rotor-Strip-Till System really works:

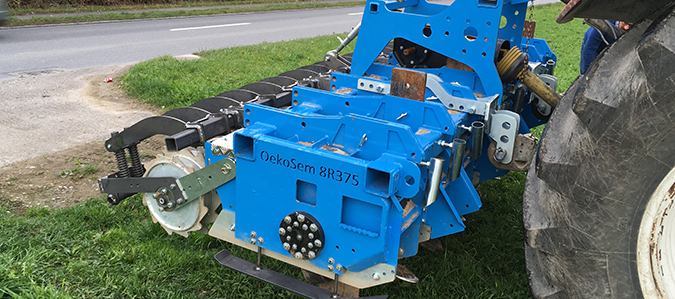

The soil in the tilled strip is mixed with the applied fertilizer, finely crumbled and therewith prepared for seeding. The sub-soiling tines which are fitted in between the rotavator knives can be easily adjusted to the desired depth in which the soil is to be loosened. Within the strip, the soil is lifted into the rotavator with the wide wing shares so that the soil is settling back down a little after the rotavator has passed. This is to avoid any hard-panning through smearing of the rotavator. At the same time, this stimulates strong root growth and a penetration of roots into even deep layers of the soil. For vegetable producers there is a new option available: An actively powered leveling roller which is planing the soil surface perfectly and leaves a very finely structured seedbed. At last, the adjustable culti packer roller is delivering the right soil to seed contact. All of this amounts to a perfect seedbed which is the best basis for strong root growth.

The soil in the tilled strip is mixed with the applied fertilizer, finely crumbled and therewith prepared for seeding. The sub-soiling tines which are fitted in between the rotavator knives can be easily adjusted to the desired depth in which the soil is to be loosened. Within the strip, the soil is lifted into the rotavator with the wide wing shares so that the soil is settling back down a little after the rotavator has passed. This is to avoid any hard-panning through smearing of the rotavator. At the same time, this stimulates strong root growth and a penetration of roots into even deep layers of the soil.

Low labor requirements by combining several operations Safe early development of corn Good soil structure simplifies ordering the aftercultures

Best protection against soil erosion Reduces nutrient runoff into waters Long greening = good nitrate protection Land cover stimulates earthworms and other soil life Fewer passes protect the ground Soil structure is improved Good carrying capacity at harvest reduces soil compaction

Rotor STRIP TILL needs a good soil structure Heavy and light soils are equally suitable Does not treat wet floors

| Plough | Reduced tillage | Row-Rotavator | |

|---|---|---|---|

| Dry matter | 71.89% | 73,82% | 74,07% |

| Dry weight (86% TM) | 7780 kg/ha | 7840 kg/ha | 7920 kg/ha |

| Relative to plough | 100% | 101% | 102% |

| Plough | Reduced tillage | No-till | Row-Rotavator | |

|---|---|---|---|---|

| Dry matter | 63.8% | 64,6% | 64,9% | 63,9% |

| Dry weight (86% TM) | 8625 kg | 8938 kg | 6044 kg | 9611 kg |

| Relative to plough | 100% | 104% | 70% | 111% |

Through the good, in-depth soil structure and soil-loosening the corn root had enough

growing space available and the plant could develop accordingly.

In contrast to some of the the plough or reduced till variants,

even after torrential rains in May, the soil remained stable in the row-rotavator variants and no water was lost.

Give us a call or send us an email and we will get back to you as soon as possible!

HEADQUARTERS

Bernstrasse 26, CH-6152 Hüswil

(Service, Ersatzteile, Verkauf CH)